Believe it or not, there is a direct relationship between the coating on a ceiling’s surface and the amount of light that is dispersed throughout the room. The better the light is disbursed, the less dependence there is on artificial lighting. And, the less dependence there is on artificial lighting, the less energy is consumed. It all depends on a couple factors and these will be discussed in detail within this article.

Light Absorption

It is commonly known that dark colors absorb more heat than light colors. A black car sitting in the sun will build up more heat inside than a white one. People in South America wear white jackets rather than black ones, because it is cooler. The darker colors attract the light and when the source of the light is the sun, it is felt in the form of heat.

Then it should appear equally obvious, that a dark ceiling will also attract the light and soak it up. To prove the point through a case study, a major banking corporation was particularly concerned about the ambient light in their banks. As a test, new light fixtures were installed in the ceiling of a poorly lit room. After the installation, the old/dark ceiling absorbed the light and it was determined that at the work level, there were 40 foot-candles registered on the light meter.

The new light fixtures remained in place and the ceiling was painted with a high quality product. New readings showed an increase to 80 foot-candles at the same work level. Obviously, the amount of light absorbed by the ceiling was reduced dramatically … a 100% improvement.

This example shows that the color of the ceiling has a major impact on the amount of lighting required in a given space. Trying to overcome excessive light-absorption by the ceiling through more and stronger artificial lighting can be expensive.

Does the Type of Paint Make a Difference

Testing has been done where different types of paint products have been tested simultaneously to measure the whiteness index. There is most definitely a correlation between the quality of the ceiling coating and the amount of light it spreads around the room.

As a rule of thumb, ceiling paints tend to be of a lesser quality than other products. A paint used on surfaces that are subjected to hard wear must be formulated to be scrubbed and resist erosion. Similarly, why should paint manufacturers invest a lot of quality in a material that will not be subjected to wear, etc? That is why the lesser quality product tends not to have the stronger pigments that are required to reflect light and not fade out as quickly.

In order to obtain the desired quality and resulting performance, it is best to seek out a specialty coating that is designed specifically for ceilings. Since many ceilings also absorb sound, an acoustical coating provides the best of both worlds.

Acoustical Coatings

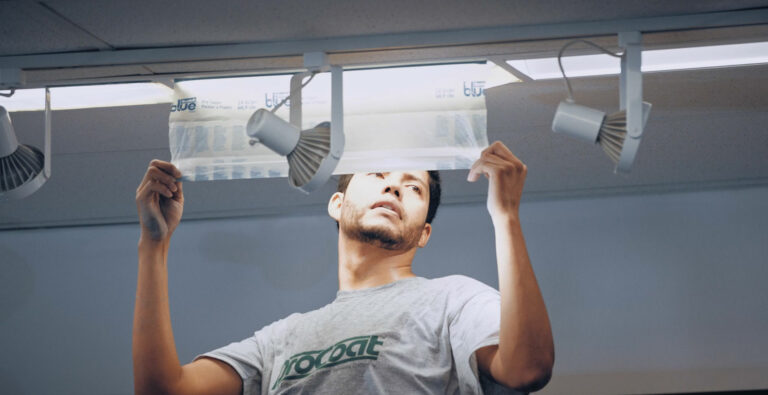

These products were initially developed as a means of restoring an old, discolored ceiling as a cost-effective alternative to replacing with new materials.

In order to promote the sale of their product over traditional paints, unique characteristics were built in to the design that sets them apart. Firstly, they protect the ceiling’s ability to absorb sound and also the fire retardant qualities as well.

And, to make them even more attractive, they tend to hold their color longer than traditional ceiling paints and distribute light more effectively.

Therefore, in order to identify a quality ceiling product and/or its manufacturer, a good place to start is the internet, where one should look for “Acoustical Ceiling Restoration.”

There, references can be found to more than one product used in this industry. The next step is to determine which of them will provide the desired performance. In this regard, it is not recommended that a selection be made, based only on verbal claims sprinkled within their marketing material.

As part of the product development process, legitimate product manufacturers have their products tested in order to ensure that it is performing as intended. These tests are conducted by independent testing laboratories and their test results are completely unbiased.

In selecting one product over another, one should make that choice based on test results that the legitimate manufacturers make readily available. The results of light reflectance testing are one of those that should be available and if not, that product should not rank as well as others that do. Aging test data can also be used to compare one product against another, in order to see which ones have the greater light index and how well it holds that advantage over time.